Research at DIT

Pioneering & Vibrant

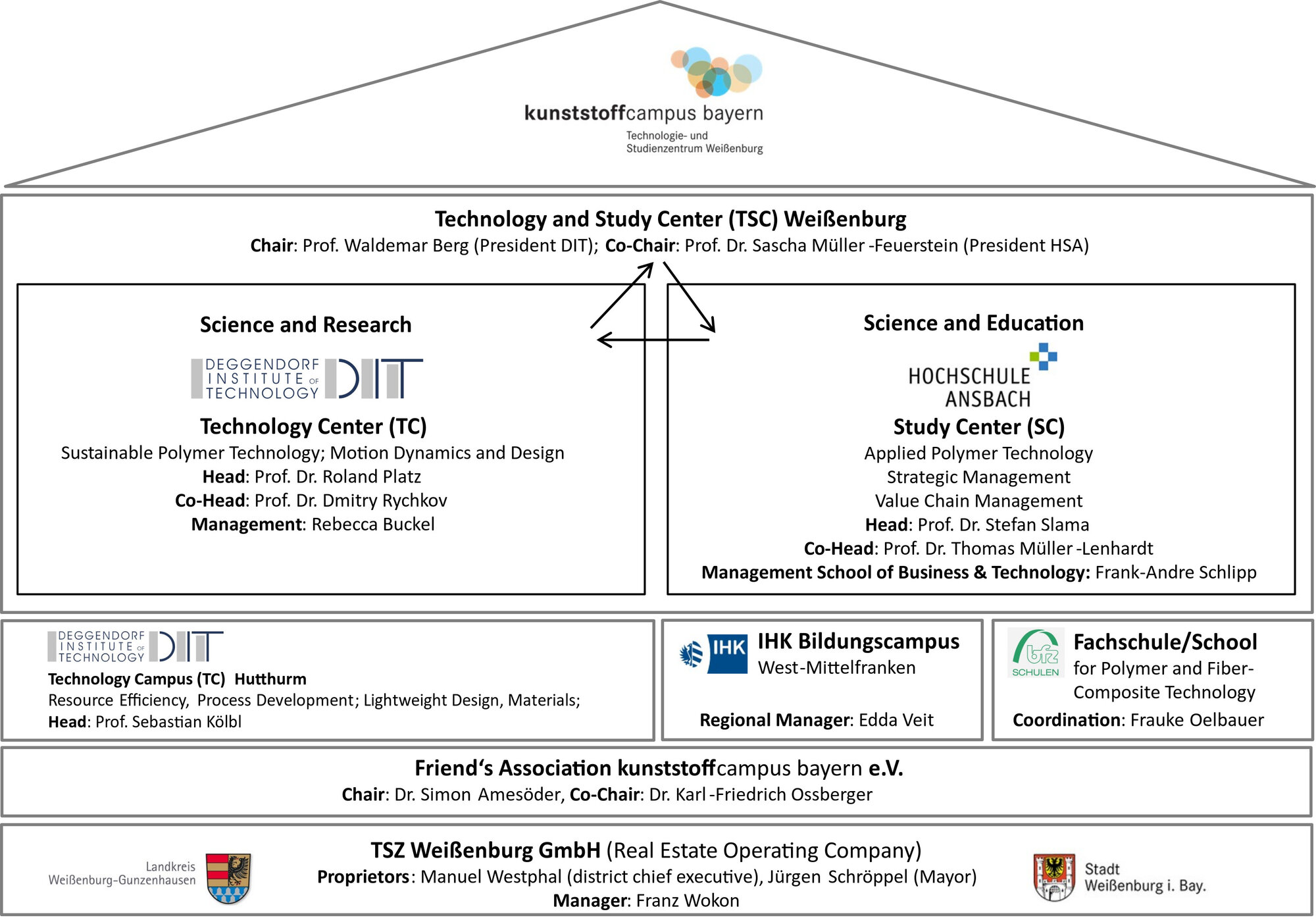

The Deggendorf Institute of Technology operates the kunststoffcampus bayern (Plastics Campus Bavaria) together with the University of Applied Sciences in Ansbach, the city of Weissenburg in Bavaria and the district of Weissenburg-Gunzenhausen. The focus of this cooperation is on networking with industry, the development and implementation of specific courses and the supervision of research and development projects. At the Technology Centre Weißenburg, scientific know-how is linked to the requirements of the industrial value-added chains in research projects. For this purpose, we develop strategies together with our partners and offer support at all times in the choice of funding opportunities. For the solution of material-related problems or in component testing, high-quality equipment is available for joint use. The Study Centre Weißenburg focuses on academic training and further education, part-time bachelor's degree courses and the possibility of obtaining individual certificates through modular courses of study or seminars.

About the campus Weissenburg

The Technology Centre (TC) Weissenburg is a technology campus of the Deggendorf Institute of Technology and forms the Technology and Study Centre (TSC) Weissenburg in cooperation with the Ansbach University of Applied Sciences. Alongside the regional plastics processing industry and educational institutions, the TSC Weissenburg is part of the Bavarian Plastics Campus set up by the district of Weissenburg-Gunzenhausen and the town of Weissenburg i. Bay.

The TC Weissenburg promotes the scientific and technical

development of

- manufacturing processes,

- component and system testing,

- functional and structural integration,

- verification and validation

with a focus on plastics and plastics composite technology.

In the long term, TC Weissenburg aims to play a leading role in research and development and as a service provider for the regional and national plastics processing industry.

The Kunstoffcampus-Bayern calls for cooperation between the Deggendorf Institute of Technology (DIT) and the Ansbach University of Applied Sciences (HSA) in the TSC Weissenburg in order to create synergies and convey a uniform image to the outside world. It bundles research and development activities of the cooperating DIT as well as study and vocational training opportunities of the cooperating HSA, the Chamber of Industry and Commerce of Middle Franconia and the Weißenburg Technical College for Plastics Engineering and Fibre Composite Technology under one roof.

In addition to the TC Weissenburg, the Technology Campus (TC) Hutthurm of the DIT is also a key element of the Kunstoff Campus. The TC Hutthurm cooperates on research and development topics relating to resource efficiency through process development, lightweight construction and materials research. The company k3-works, an independent subsidiary of Gentherm based in Treuchtlingen in the immediate vicinity of Weissenburg, carries out environmental and service life tests in laboratory and office space rented specifically at the Kunstoff Campus.

The Förderverein des Kunststoffcampus Bayern e.V. promotes and develops the operation of the KCB; the association creates and maintains additional contacts between science, industry and the public, particularly in the district of Gunzenhausen-Weißenburg and in the town of Weissenburg. The chairman of the association is Dr Simon Amesöder (RF Plast GmbH, Gunzenhausen), the deputy chairman is Dr Karl-Friedrich Ossberger (Ossberger GmbH & Co. KG, Weißenburg).

Bildnachweis: Roland Platz, Kunststoffcampus Bayern Weißenburg

In September 2019 and March 2021, the two newly appointed professors at the Deggendorf Institute of Technology, DrDmitry Rychkov and Dr Roland Platz, began their work as scientific directors at the TC in Weissenburg. Dr Rychkov represents the field of "Sustainable Plastics Technology"; his focus is on function-integrated and function-enhancing materials. Examples include electroactive polymer films, electrical insulation materials/compounds, actuators and sensors. Dr Rychkov is also committed to the circular economy in the plastics industry. Dr Platz represents the field of "Motion Dynamics and Design"; his focus is on the condition control of structural dynamic systems. Examples include the identification and simulation of the load spectra of load-bearing systems such as frame and bearing structures, spring-damper systems in mechanical engineering, load-bearing structures in civil engineering, the vibration, stability and load redirection control of such systems as well as the evaluation of data and model uncertainty.

Together, the two working groups focus on the further development of manufacturing processes, structural integration as well as verification and validation in the early development phase of plastic components and systems. This results in a wide range of services.

In order to promote and support the concerns and interests of the kunststoffcampus bayern in the best possible way, a support association was founded in February 2015 on the initiative of the district and the entrepreneurs Dr Simon Amesöder, Gunzenhausen, and Dr Karl-Friedrich Ossberger, Weißenburg.

The purpose of the association is to promote the development and operation of the "kunststoffcampus bayern - Technology and Study Centre", which was officially inaugurated on 27 March 2015.

The aim of the association is to generate funds to promote science and research, vocational training and academic education and training. Among other things, this is to be achieved by creating a climate of dialogue between science and business, by providing financial support and organising scientific events and by initiating and expanding contacts with relevant institutions outside the Altmühlfranken region.

In order to publicise and support the concerns and interests of the kunststoffcampus bayern project in the best possible way, a support association was established in February 2015.

All natural or legal persons who identify with the objectives of the kunststoffcampus bayern are welcome as new members.

Friends' association:

Chairman: Dr Simon Amesöder, RF Plast GmbH

Deputy Chairman: Dr Karl-Friedrich Ossberger, Ossberger GmbH + Co KG.

Treasurer: Rudolf Dürr, SWR Dürr Albrecht Körzendörfer Partnership

Secretary: Sabine Unterlandstaettner, Zukunftsinitiative altmühlfranken

Other board members:

- Andre Baumann, Verpa Folie Gunzenhausen GmbH

- Andreas Gebhardt, SMA Holding GmbH

- Harald Höglmeier, HP-T Höglmeier Polymer-Tech GmbH & Co. KG

- Michael Meyer, m3profile GmbH Kunststoffverarbeitung

- Klaus Rößler, Schnitzer Group GmbH & Co. KG

The following links are available for further information and members of the association:

https://www.kunststoffcampus-bayern.de/foerderverein/

https://www.kunststoffcampus-bayern.de/mitglieder-des-foerdervereins/

The Technology Centre Weissenburg combines expertise in research and development in the field of plastics and their value chain. The focus is on applied research and development. Within the four fields of activity described above, future-oriented questions are dealt with up to the prototype phase. Furthermore, the technology centre supports the subsequent implementation and use of research and development results.

Equipment

In plastics processing, preparation is first necessary in order to produce a processable plastic mass from the plastic raw material, e.g. crushing (granulating, grinding) and mixing in solid and plastic states. As a rule, up to 50% of additives and fillers are added to the plastic with the aim of distributing them as homogeneously as possible in the mass and realising the desired mechanical, thermal, chemical and electrical properties in the plastic products. During plasticising, the dry premixed plastic mass is melted and further homogenised during kneading using single or multiple screw systems. After preparation, plastic products are generally further processed in large quantities using conventional manufacturing processes such as compression moulding, injection moulding and blow moulding, as well as extrusion, foaming, calendering, rotational moulding, etc. to produce components, films, foams, insulation, packaging, etc. The plastics most frequently processed into products using traditional methods are thermoplastics made from hydrocarbon compounds such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and polyethylene terephthalate (PET).

2K-Injection moulding machine Twin-screw extruder Plasma system

2K-injection moulding machine KM CXL 130-750/380

twin-screw extruder KM ZE 25Ax45D

miniextruder line EXS-AN-0100

moisture analyser Aquatrac-3e

blasting machine

arburg dryer Thermolift 100-3

Mobiler Dryer Simar KTX120-102

laser cutting machine

plasma system Plasma Coat PCU3D

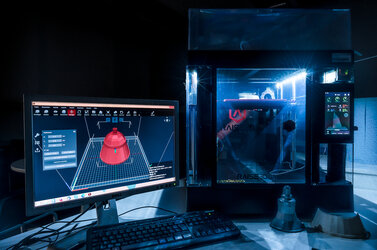

Since the 1990s, additive manufacturing processes or fused deposition modelling (FDM) have become increasingly important in plastics processing compared to conventional manufacturing processes. Compared to conventional processes, FDM generally allows customised production, high flexibility in shaping and low production costs without significant restrictions in the manufacture of complex geometric shapes of thermoplastic products. Small quantities of customised products can be produced economically. Finally, FDM enables the combination with additives and fillers for the functional integration of enhanced mechanical, thermal, chemical and electrical properties, e.g. with aluminium oxide, glass fibre, iron particles, fly ash/carbon black particles and carbon fibres or carbon nanotubes.

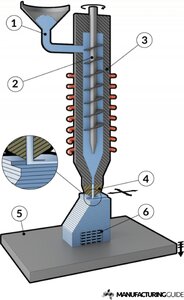

The Fused Granular Fabrication (FGF) process is a special FDM process that does not require the production of filaments as a preliminary product for the additive production of plastic compounds, as is the case with the more widely used Fused Filament Fabrication (FFF) process. As seen in the granulate 3D printing (T-Rex 0609), the plastic granulate (1) is plasticised by being propelled by an extruder screw (2) through a heated zone (3) consisting of three heating belts and exits through the extruder nozzle (4) to build up structures (6) layer by layer on a heated platform (5).

By dispensing with the filament as an intermediate product, the FGF process simplifies the production of additively manufactured compounds, allowing an uninterrupted process from the mixing of granulates with additives and masterbatches or colour pigment powder, melting, conveying and printing to plastic components. This makes it possible to process recycled plastic granulates, pellets or flakes directly. There is no need for an additional process to produce a filament from granulates, as is the case for the FFF process.

The group is currently researching variants for process control of the 3D printer in order to minimise typical production errors in the FGF process and to maximise the homogeneity of the manufactured compounds or to realise them in a customised manner.

granulate 3d printing (t-rex 0609)

3d printer felix pro 2

Investment was co-financed by the European Union through the European Regional Development Fund.

3d printer raise3d pro2

drying cabinet fed115

top-mounted dryer system

Sectional view of the structure of the 3D printer

The quality and safety of plastic products are of the utmost importance. Inadequate materials or faulty components can not only cause expensive production downtime, but also jeopardise safety. This is why material and component testing is a crucial step in product development and manufacture.

TC Weissenburg has the most modern technologies and advanced testing procedures to meet the highest quality standards. The reproducibility of the measurement results is largely dependent on the quality of the test specimens, which is why various machines are available for specimen preparation in order to carry out the corresponding tests. The tests can be carried out on test specimens as well as on components.

universal testing machine

rapid weathering unit quv

xenon test chamber q-sun xe-1

climate / temperature shock chambers

pendulum impact tester

meltflow melting index tester

The investments were co-financed by the European Union via the European Regional Development Fund. Universal testing machine

hardness tester nova360

grinding and polishing machine lapo5

table cutting machine labotom-5

ultrasonic cleaning equipment

Microscopy and the analysis of plastics provide a deep insight into their composition, structure and properties. With the help of high-resolution microscopes, defects, impurities and irregularities that can affect quality can be recognised. The thermal and chemical analysis of plastics is crucial in determining their composition and properties. Using techniques such as infrared spectroscopy, we can decipher the chemical structure of plastics. This enables us to ensure that the right materials are used and that quality standards are met.

The microscopy and analysis of plastics covers various areas such as quality control, defect analysis and material development.

FT-IR microscope and spectrometer

The investments were co-financed by the European Union via the European Regional Development Fund.

differential calorimeter - DSC 214 Polyma

The investments were co-financed by the European Union via the European Regional Development Fund.

thermogravimetry - TGA TG 209 F1 Libra

The investments were co-financed by the European Union via the European Regional Development Fund.

light microscope Keyence VHX5000

The investments were co-financed by the European Union via the European Regional Development Fund.

Light Microscope Keyence VHX5000

spectrophotometer Konica-Minolta CM-5

rheometer 102e

thermal conductivity meter

Mobile Surface Analyzer Krüss

Thermoanalysator Triton DMA 2000

The focus is on the controlled condition monitoring of functionally integrated structural dynamic systems. Examples include the identification and simulation of the load spectrum of load-bearing systems such as frame and bearing structures, spring-damper systems, load-bearing structures, the vibration, stability and load redistribution control of such systems as well as the evaluation of reliability and data and model form uncertainty using numerical verification and experimental calibration and validation procedures based on Bayesian inference methods.

The focus is on the controlled condition monitoring of functionally integrated structural dynamic systems. Examples include the identification and simulation of the load spectrum of load-bearing systems such as frame and bearing structures, spring-damper systems, load-bearing structures, the vibration, stability and load redistribution control of such systems as well as the evaluation of reliability and data and model form uncertainty using numerical verification and experimental calibration and validation procedures based on Bayesian inference methods.

Connection of a voice coil actuator with an oscillating mass and force

sensor for the simulation of passive and active vibration isolation

Electrical movement platform on eight legs (octopods)

Electrical movement platform on eight legs (octopods)

Payload: 400 kg (at 4 g)

Acceleration: 40 m/s² (in all directions)

Speed: 2,0 m/s (x/y - Direction); 1,1 m/s (z - direction)

Deflection: ± 750 mm ((x/y - Direction); ± 380 mm (z - direction)

Rotational acceleration: 450 °/s² (in all directions)

Rotation: 25° (um x/y - Achse); 35° (at z - Axis)

Movement platform

Temperature range: -40 °C to +70 °C

Temperature range: -40 °C to +70 °C

Heating / cooling rate: 2 K/min

Usable volume: 1.000 x 1.000 x 1.000 (B xT xH in mm)

Temperature control: - Boost function

- Ramp, curve and point control

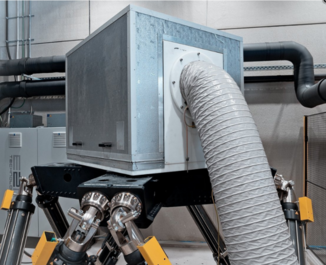

The motion platform realises experimental motion sequences and vibration excitations to which systems and system components in vehicles on roads, rails and in factories, in robotics as well as in aerospace technology and marine engineering are exposed. If required, a mounted climate chamber enables the experimental simulation of environmental influences during the motion and vibration simulation.

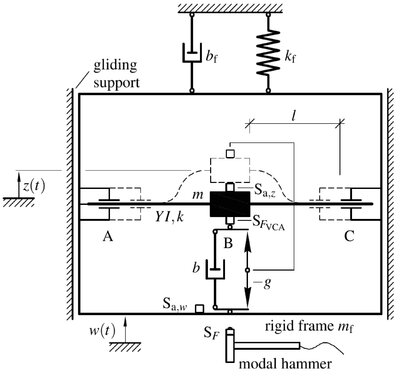

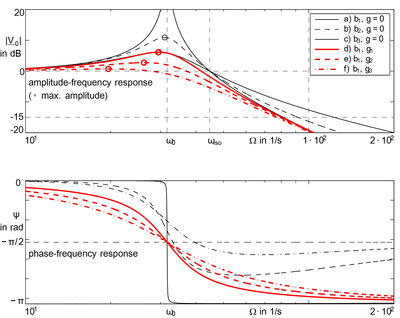

Movement platform with climate chamber

The aim of the investigations is to identify and evaluate the uncertainty in various mathematical models for predicting passive and active vibration isolation. In this context, active vibration isolation means that an additional force controlled by velocity-proportional feedback (amplification factor g) significantly increases the vibration isolation effect compared to passive vibration isolation without the additional force. As seen in the conceptual design, a two leaf springs (bending stiffness YI and stiffness coefficient k) with adjustable lengths l and a voice coil actuator (damping coefficient b, amplification factor g). The frame is also mounted to vibrate via elastic bands (damping coefficient b_f≪b and stiffness coefficient k_f≪k). A modelling hammer generates an impulse on the frame, which is passed on to the vibrating mass m as a displacement excitation and causes it to vibrate.

The aim of the investigations is to identify and evaluate the uncertainty in various mathematical models for predicting passive and active vibration isolation. In this context, active vibration isolation means that an additional force controlled by velocity-proportional feedback (amplification factor g) significantly increases the vibration isolation effect compared to passive vibration isolation without the additional force. As seen in the conceptual design, a two leaf springs (bending stiffness YI and stiffness coefficient k) with adjustable lengths l and a voice coil actuator (damping coefficient b, amplification factor g). The frame is also mounted to vibrate via elastic bands (damping coefficient b_f≪b and stiffness coefficient k_f≪k). A modelling hammer generates an impulse on the frame, which is passed on to the vibrating mass m as a displacement excitation and causes it to vibrate.

Overall setup with measuring computer (left), amplifier and filter bank (centre) and test stand (right)

Conceptual design of the trainer Amplitude and phase-frequency curves for different attenuations and amplifications

Model hammer: PCB Piezotronics, model: 086C03 for ICP impact hammer,

acceleration sensors: PCB Piezotronics, model: 333B52,

model hammer force sensor: PCB Piezotronics, model: 086C03,

force sensor of the plunger coil actuator: PCB Piezotronics, model: 086C02,

plunger coil actuator: Accel Technologies, model: VLR0113-0089-00A,

real-time controller: dSpace™GmbH, model: DS1104 R&D Controller Board,

filter bank: Kemo Limited, BenchMaster 21M,

power amplifier: Tira GmbH, model: BAA60.

The public's perception of plastics is very much characterised by their environmental aspects.

For example, they are at the forefront of packaging materials, which are responsible for microplastics, greenhouse gases and the general throwaway society. In specialist circles, plastics are primarily seen only as construction materials. However, plastics can do much more. Thanks to their electroactive properties, plastics can become smart materials. For example, by anchoring electrical charges on the surface, polymer films can be given sensory and actuating properties. Such electromechanical transducers are used today in mobile electronics, the automotive industry and the aerospace industry. The associated processes and mechanisms of charge storage and charge transport are being investigated at TC Weissenburg using state-of-the-art measurement technology.

LCR meter (Instek) & digital multimeter (Keithley)

LCR-Meter Instek LCR-821

6,5 Digit Digital multimeter Keithley DMM6500

high voltage amplifier TREK Model 5/80

high voltage amplifier TREK Model PD 0531

Precision heating plate precision therm PZ35

heat press Vogt laboratory press P200S

laser cutter Makeblock Laserbox MLP-K503-40W

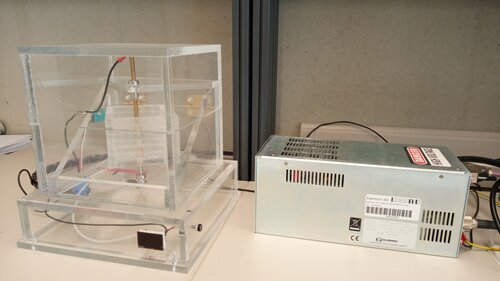

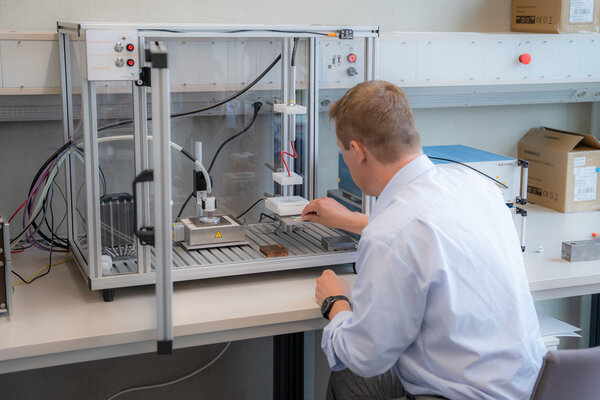

The setup is used for controlled charging and discharging of polymer samples. Charging takes place via corona discharge by depositing negative or positive charges on the sample surface. The charge density or surface potential is very precisely pre-set and controlled. The samples are then discharged isothermally or thermally stimulated and the decay of the surface potential is recorded and stored on the computer as a discharge curve. The discharge curves provide important information about the processes of charge storage and charge transport in dielectrics. These findings are then used in the development of new types of actuators and sensors as well as high-voltage insulation.

The setup is used for controlled charging and discharging of polymer samples. Charging takes place via corona discharge by depositing negative or positive charges on the sample surface. The charge density or surface potential is very precisely pre-set and controlled. The samples are then discharged isothermally or thermally stimulated and the decay of the surface potential is recorded and stored on the computer as a discharge curve. The discharge curves provide important information about the processes of charge storage and charge transport in dielectrics. These findings are then used in the development of new types of actuators and sensors as well as high-voltage insulation.

Test rig for charging and thermally stimulated discharging of plastics

bipolar power supply unit FUG HCB 7-6500

high voltage amplifier FUG HCP 35-35000

contactless electrostatic voltmeter TREK 341A 20kV

contactless electrostatic voltmeter TREK Model 370 3,5kV

controlled hotplate (G. Maier)

Dielectric strength (or dielectric strength) is defined by the voltage that may be present in the insulating material without a voltage breakdown occurring. This is an important material property, especially in the age of electric mobility and renewable energies, where very high electrical voltages have to be transmitted and converted. The set-up consists of a measuring cell with two electrodes. The plastic sample is placed between the electrodes and the voltage is increased linearly until a voltage breakdown occurs. The upper limit for the respective material is then reached and documented.

Measuring cell with high-voltage power supply 60kV Glassman PS/MK60 NO1.2-22

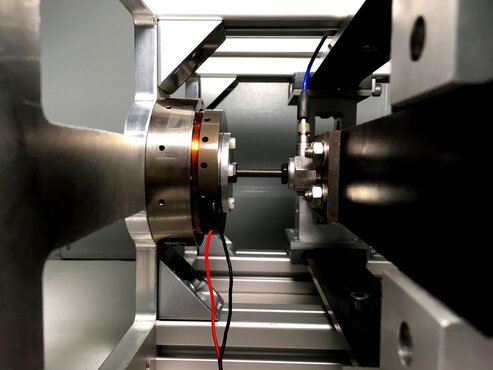

Piezoelectricity is the occurrence of an electrical voltage on solids when they are elastically deformed. Various modern actuators and sensors are constructed on the basis of piezoelectric materials. Some polymer materials have piezoelectric properties, making them so-called smart materials. The experimental setup is used to measure their piezoelectric coefficients. The samples are excited using a sinusoidal force and the resulting voltage signals are recorded with the measuring amplifier.

Piezoelectricity is the occurrence of an electrical voltage on solids when they are elastically deformed. Various modern actuators and sensors are constructed on the basis of piezoelectric materials. Some polymer materials have piezoelectric properties, making them so-called smart materials. The experimental setup is used to measure their piezoelectric coefficients. The samples are excited using a sinusoidal force and the resulting voltage signals are recorded with the measuring amplifier.

Measurement of piezoelectric coefficients in polymerising sensors

signal generator voltcraft FG-30802

power amplifier for Shaker Brüel&Kjaer Type 2718

Shaker Brüel&Kjaer Type 4810

2-channel measuring amplifier Brüel&Kjaer Type 2690

Mixed Domain Oszilloskop Tektronix MDO34

2k injection moulding machine km cxl 130-750/380

On the existing 2K injection moulding machine, the second additional injection unit injects into the moving mould half in the L position on the non-operator side. This allows certain areas in the injection mould to be released for a second component (such as regranulate= by sliders after a pre-moulded part has been produced. For this purpose, the mould element can be rotated around the horizontal axis. The rotation brings the pre-moulded part into the cavity for the second injection process, which can be used, for example, to back-mould previously produced high-quality visible surfaces at low cost.

km ze 25ax45d-utxi twin-screw extruder

With the twin-screw extruder, a reduction of the testing costs is possible, since even small quantities can be produced without any problems. All stages of the compounding process can be assessed reliably and quickly by simply removing the screws. The barrel-screw configuration can be precisely matched to your process engineering requirements thanks to the modular design principle. The selected machine configuration can be easily controlled, regulated and monitored at any time via the touch display.

3d printer felix pro 2

With the smart Felix Pro 2 it is possible to create layer by layer precisely fitting functional plastic parts with a smooth surface. Thanks to the fully automatic calibration of the printing bed and the dual extruder, even the creation of geometrically complex objects is easy and material saving. The Dual-Extruder also makes it possible to print with two different materials or colours at the same time, including the use of a support material. Only a 3D model as STL, OBJ, 3DS, AMF file is required.

Investment was co-financed by the European Union through the European Regional Development Fund.

mini extruder line exs-an-0100

With this single-screw line extruder, a few grams to kilograms of a polymer can be extruded per hour at speeds ranging from 25 to 100 1/min. Thin fibres, tubes or filaments can be produced via exchangeable die tools and screen plates. The plant is equipped with a 10mm diameter screw and a cooled feed zone. In addition, short preasure peaks can be intercepted by means of fully automatic pulsation suppression.

movement platform

On the trail of reality by mapping dynamic movements in the laboratory with defined influencing factors on the motion platform. The system is based on eight high-resolution actuators acting on a common platform. With this test bench, dynamic movements up to 20 Hz in translation and rotation direction as well as static positions of all components can be simulated. In combination with a climatic chamber, these motion studies can be performed with a maximum acceleration of 40m/s² (4-fold acceleration due to gravity) under different temperature conditions (-40°C to + 70°C). The eight-legged test rig at kunststoffcampus bayern allows dynamic movements in translation and rotation direction up to four times the acceleration due to gravity. This means that almost all motion sequences of land/air/water vehicles can be reproducibly mapped in the laboratory. The parts and components to be tested are in reality exposed to the most varied environmental conditions. Therefore, most tests can only be carried out with test drives directly in the vehicle and in the countries where the required climatic conditions prevail. With the help of the existing motion platform and the integrated climate control system, it will be possible in future to carry out these tests directly in the laboratory in the most compact space using realistic motion profiles and constant climate conditions. Movements generated by a moving car, for example, can be simulated on the platform with sine curves as well as freely defined trajectory curves. The simulation of test drives with a distance of several thousand kilometres is possible within a few days in the laboratory under precisely defined climatic conditions, making these load tests efficient and cost-effective. Driving directly in the vehicle is therefore no longer necesary on a large scale. The cooperation in this project is currently taking place with partners from the industry.

- Proof of operational stability

- Complex stress history

- Functional testing of components

- Development of control algorithms

- Lifetime validation

- Residual stresses in components

- Model-based testing of mechatronic components

universal testing maching

In the unversal testing machine of Hegewald & Peschke MPT GmbH standard samples as well as finished products and components can be tested with regard to their mechanical properties. Due to the high versatility of the system, tensile, compression, bending or torsion tests can be performed easily and reliably. With the additionally available furnace the machine becomes an absolute specialist and allows tests at elevated temperatures.

- Max. 50 kN

- Testing of standard tension rods according to DIN EN ISO 527

- Production of individual clamps for component testing

melt flow index tester meltflow

With the compact testing device, MFR values in g/10 min, MVR values in ccm/10 min and the melt density in g/ccm can be determined easily reliably.

- ASTM D 1238, Method A and B

- ASTM D2116-3159-3307-3364

- BS 2782-720 A

- AFNORT 51-016

- ISO 1133-UNI 5640

Investment was con-financed by the European Union through the European Regional Development Fund.

quv rapid weathering device

With the QUV rapid weathering instrument, the effects of the short-wave UV spectrum of sunlight can be reproducibly simulated. The possible spectra offer a peak wavelength of 340 nm (UV-A) or 313 nm (UV-B) for damage in even less time. The optional condensation mechanism allows the test speciments to be exposed to a condensation cycle to simulate the typical damage of outdoor conditions.

xenon test chamber q-sun xe-1

With the Q-Sun Xe-1 Xenon test chamber, the effects of the full solar spectrum can be reproducibly simulated. The spectrum used corresponds to the daylight filter to the light of the midday sun in summer. Due to this accelerated aging, long-term damage can be reproduced in test series of a few days or weeks. Optionally, the influence of moisture can be simulated by a water spray device. Weathering can take place automatically around the clock.

climatic / temperature shock cabinets

The test chambers for climate and temperature tests are used to simulate accelerated ageing of plastics due to temperature effects.

ft-ir microscope and spectrometer

The combination of infrared microscopy and spectroscopy represents a complete system for routine analytical tasks and offers highest reliability in the verification and identification of plastics.

- Transmission and ATR

- Gas cell coupled with TGA

Investment was co-financed by the European Union through the European Regional Development Fund.

dsc 214 polyma

The DSC 214 Polyma is specially designed for the characterisation of polymers. The instrument combines the classical measurement of heat flow with heating and cooling rates up to 500K/min. Thus, temperature profiles relevant to processing with a maximum temperature of up to 600°C can be simulated.

Investment was co-financed by the European Union through the European Regional Development Fund.

tga tg 209 f1 libra

Thermogravimetry (TGA) enables fast and comprehensive material characterisation by measuring the temperature-related mass change. Here the evaporation behaviour is considered. For this purpose, the vacuum-tight thermos, microbalance can be heated up to 1100 °C. By coupling the TGA to the FT-IR spectrometer, the released gases of the volatile sample components can be analysed directly.

Investment was co-financed by the European Union through the European Regional Development Fund.

keyence vhx5000 light microscope

The Keyence VHX5000 is more than just an ordinary reflected light microscope. It allows you to capture a deep-focus image quickly, easily and in real time without having to focus. With the two swivel lenses, magnificaitons between 20x and 2000x can be achieved without conversion. The extension of the image dynamics by HDR technology leads to even better resolution and clearer contrasts. In addition to single image acquisition, it is also possible to create panoramas of larger objects. With the help of the "Easy Mode" a quick access ti extended functions is possible without long searching. The whole workflow is optimised for user-friendliness and always consists of the points: View, capture, measure. By extending the device with a borescope lens, it is even possible to look right into the component. Through an opening of 4mm, the borescope can be inserted into the component to a depth of around 15cm and bring "light into the dark" with 10x magnification.

Investment was con-financed by the European Untion through the European Regional Development Fund.

konica-minolta cm-5 spectrophotometer

The Spectrophotometer CM-5 enables the colour measurement of solid, pasty and liquid materials by illumination in reflection or transmission. It is a tabletop device with measuring apertures from 3 to 30mm for solids. The large transmission chamber for liquids, together with the different petri dishes and cuvettes, extends the great flexibility. On a 5.7" LCD screen the results can be displayed in different colour spaces.

Projects of the Campus weißenburg

- Title of the project:

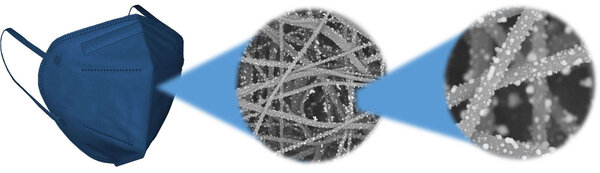

"Microscopic mechanisms of charge stabilisation in electrically charged fine-fibre electret materials (MIKROLAST-EFFECT)"

- Funded by: Bavarian Research Foundation

- Co-operation partner: IREMA Filter GmbH

- Term: 01.10.2022 - 31.09.2025 (36 months)

Initial situation and objectives

The respiratory masks and air filters used to combat viral diseases such as the Covid pandemic must be electrically charged in order to achieve a high filtering effect. However, the materials commonly used have very low charge stability. The project aims to research and develop new and efficient methods for charge stabilisation in filter fibres.

Procedure / Methods

In the meltblown process, molten polymer is converted into fine filter nonwovens via nozzles. In order to achieve high filtration efficiency, the nonwovens must be electrically charged. Due to the low charge stability in conventional meltblowns, the filtration efficiency decreases relatively quickly. The aim of this project is to investigate the molecular mechanisms of charge storage in meltblown fibres. Based on this, methods for increasing the charge density and for charge stabilisation are to be developed. The main project idea involves the targeted control of charge stability and charge density in electrostatically charged polymer fibres using a combination of physical and chemical methods. Films, individual fibres and meltblown nonwovens are charged in corona discharge and the discharge processes are systematically investigated under the influence of external factors such as temperature, humidity and solvent vapours. The knowledge gained about charge transport is used to develop charge stabilisation methods. On a microscopic level, it means that the charge carriers are selectively stored in deep adhesion sites and the polymer materials are modified in such a way that new deep adhesion sites are created in addition to the existing adhesion sites. The two solutions are realised through thermal treatment, optimisation of the charging processes, surface modification of nonwovens and granules and the addition of additives by means of compounding. The technological approaches developed are used for the production of near-series demo filter nonwovens, which are tested and validated under series conditions in meltblown processes.

Results

The expected results of the project and the most important innovative features can be summarised as follows:

- Scientifically sound and targeted control of material parameters through a combination of physical and chemical treatment methods.

- For the first time, surface treatment methods will be used to improve charge storage in meltblown materials.

- Not only the concentration but also the depth of the adhesion points is increased. This increases the stability and density of the stored charges and accordingly improves the filtration efficiency.

- New and deeper adhesion points on the fibre surfaces make the filters more resistant to environmental influences such as humidity or chemical vapours. The latter are particularly important in medical technology.

Conclusion / Outlook

The project aims to develop a technology concept for the production of synthetic filter media with outstanding properties. In addition, the electrically charged nonwovens can also exhibit piezoelectric properties. This opens up new perspectives for the application of these materials in the field of actuators and sensors. Particularly interesting are the applications in the field of energy harvesting, for which lightweight and conformal nonwovens can be used for the purpose of energy recovery. There is also a need for temperature-stable electret filters for the filtration of microplastics and for abrasion particle filtration in the automotive sector. The applications mentioned above only make sense or are even possible if there is a high charge stability. In this sense, the project results will open up new areas of application for already established technologies.

Image: Charging in corona discharge, thermally stimulated discharge of films and nonwovens

Please contact us for further information!!!

Prof. Dr. Dmitry Rychkov

Dr. Anna Guliakova

M.Sc. Dominik Weiß

This project is funded by the European Social Fund.

This project is funded by the European Social Fund.

- Title of the project:

"#DieWirkt - The training initiative for resource-saving plastics technology

- Maßnahmen-ID: StMBW-W-IX.4-6-210039

- Duration: 01.07.2021 - 31.12.2022

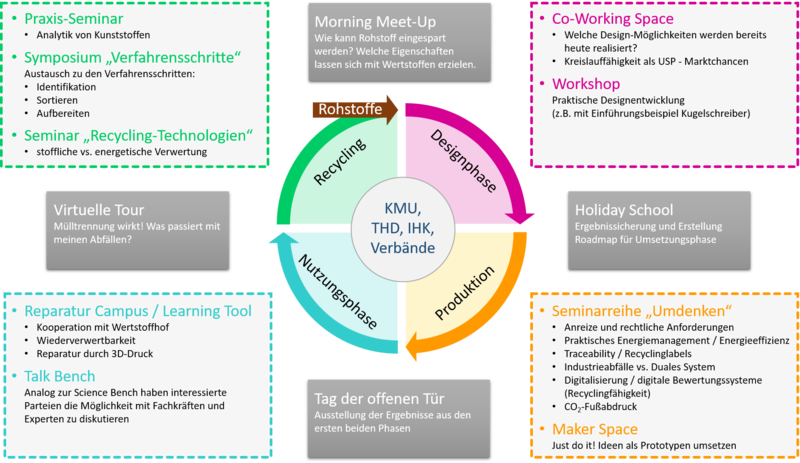

The topic of "circular economy in the plastics industry" will become more decisive for business success in the near future.

Accordingly, the focus must be placed more intensively on resource-conserving and environmentally conscious development and production.

The further education initiative for resource-conserving plastics technology (#DieWirkt) aims to make it easier for small and medium-sized industrial companies to access the key areas of "sustainability", "recycling" and "circular economy" free of charge. To this end, the Deggendorf Institute of Technology (THD) at the Weißenburg site and the IHK Akademie Mittelfranken will act as mediators of topic-specific knowledge and practical experience, and corresponding certificates can be acquired through regular participation. The training concept is based on the cycle of the circular economy to create links between the plastics fields of "design", "production", "utilisation" and "recycling". Alternative offers enable the successful implementation of the project even if the pandemic situation remains tense.

Industrial companies are essential for realising the goals of the "European Green Deal". Specific measures must be taken to further strengthen companies and support them in the transformation process. As a member of the Bundesverband mittelständische Wirtschaft e.V. (BVMW), we are interested in initiating the transfer of knowledge between small and medium-sized enterprises. In cooperation with the BVMW, we work out at the beginning of the funding project which topics are of great interest. This enables the participants to help shape the learning content for the various further education fields within the framework of #DieWirkt. We are currently looking for companies and cooperation partners from the various phases of the product cycle in order to initiate a functioning circular economy for people, regions and cities.

Project goals

The aim of #DieWirkt is to network the regional small and medium-sized business structure through dialogue with associations and research and to promote the transfer of knowledge among all those involved:

- Finding potential for transformation towards more sustainability

- Providing impetus for the internal organisation of the circular economy

- Initiating and communicating examples of good practice

- Jointly developing recommendations for policy makers

Termine der Netzwerktätigkeiten

- 13.07.2021 - Kick-off event

- 10.08.2021 - Recyclates workshop

- 14.09.2021 - Value creation workshop

- 12.10.2021 - Seminar on plastic packaging

- 09.11.2021 - no longer applicable

- 14.12.2021 - "System change" workshop with Andreas Jenne

- 11.01.2022 - Virtual network meeting

- 08.02.2022 - Marketing/communication: Positioning your own strengths well

- 08.03.2022 - Standardisation and digitalisation with Christian Schiller (cirplus) and Felix Philipp (SYSTEMIQ)

- 26.04.2022 - Excursion to Barthmann Kunststoff Recycling GmbH

- 10.05.2022 - Start-ups present ideas for sustainable plastics technology

- 14.06.2022 - Panel discussion - dialogue between politics, associations, business and science

- 02.07.2022 - Info day at the kunststoffcampus with FragFritz! from TU Clausthal

- 12.07.2022 - Material flow cost accounting with the Resource Efficiency Centre Bavaria

- 13.09.2022 - Excursion to Sysplast GmbH

- 11.10.2022 - Workshop „Circular Design“

- 08.11.2022 - Establishing circular business models - how does the transformation pay off?

- 13.12.2022 - Closing event

For more information, please contact us or visit us at www.kunststoffcampus-bayern.de!

Prof. Dr. Dmitry Rychkov

- Title of the project:

"Development of metallised 3D base bodies for the application of electrical conductor tracks on any free-form surfaces without free-form surfaces without wet-chemical processes for the production of LED lamps"

- Funding reference number: ZF4647001LT8

- Co-operation partner: DOTLUX GmbH

- Run time: 01.01.2019 - 31.12.2021 (36 months)

Initial situation and market demand

Traditional lamps are increasingly being replaced by modern semiconductor-based light sources. They are characterised by significantly higher energy efficiency and performance. In recent years, light-emitting diodes have become a widely available alternative for almost all lighting solutions. Compared to classic incandescent lamps, LEDs have a significantly better eco-balance, protect the environment and therefore save electricity and money.

The circuit carriers of many LED lamps are currently based on a 2D layout, such as the retrofit LED street lamp (see illustration) from Dotlux GmbH in Weißenburg, Bavaria. To generate a high beam angle, several circuit boards have to be aligned in a circle on a base in complex assembly steps. The circuit layout and the associated components (LEDs, resistors, diodes, etc.) are applied to separate 2D printed circuit boards. To dissipate the heat generated, the individual PCBs currently have to be mounted on a central heat sink using heat-conducting paste. The manufacturing process for the required 2D PCBs is not environmentally friendly due to the use of etching chemicals and the entire lamp assembly process is time-consuming.

Using an innovative dry manufacturing process known as direct metallisation, electronically conductive tracks are applied directly to thermoplastic surfaces using a combination of injection moulding, screen printing, laser and plasma technology. This process does not require any harmful products such as etching agents (iron-3-chloride, aminium persulphate) or copper to apply the conductive tracks. The components are also usually made from recyclable thermoplastics and are therefore not critical when it comes to disposal.

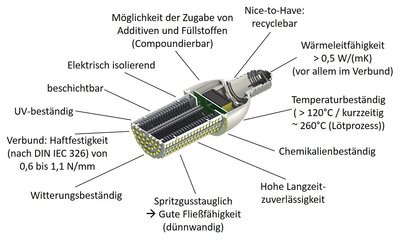

Definition of required properties

The properties of the lamp body material were defined together with the project partner, whereby various factors had to be taken into account. On the one hand, in addition to the good compoundability of the raw materials, the possibility of coating with an adhesion of at least 1.1 N/mm had to be achieved. On the other hand, the material had to be electrically insulating, but still have high thermal conductivity as well as temperature and chemical resistance. Options for recyclability were also taken into consideration.

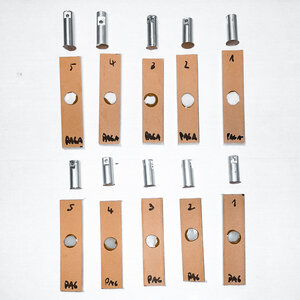

Material selection, compounding and injection moulding of test specimens

At the start of the project, the following thermoplastic materials were processed and metallised by injection moulding as part of a master's thesis:

- HDPE (Silon connections Taborex - Ta1108)

- LDPE (DOW640C Natur)

- PA6 (TechnylC206 Natur)

- PA6 (Durethan BKV 15H 1.0+ 30. + 20% Al2O3 + 15% Glass flakes)

- PA66

The investigation of the polyamides initially showed the best results in terms of metallisation due to the easily coated surfaces. In order to improve the thermal conductivity, Al2O3 was selected to reinforce the polymer matrix and improve the low thermal conductivity of the polymer matrix. Aluminium oxide also serves as a flame retardant.

Derived from the investigations with LDPE, PA6 with Al2O3 and PA6 natural as well as further detailed research, the further material selection fell on a polyamide 6 (PA6) or PA66 and a polybutylene terephthalate (PBT), each with aluminium oxide (Al2O3) and a glass fibre powder as filler. These compounds were processed into free-flowing masses using a twin-screw extruder. Two-dimensional test specimens were then produced from them via injection moulding.

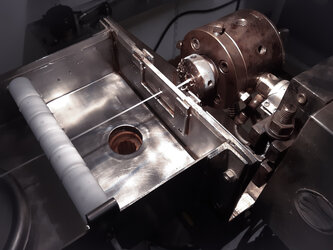

Coating via DDM and assembly of 2D bodies

The plasma system for digital direct metallisation (DDM) at the Technology Centre has an integrated 6-axis robot. This enables spatially resolved coating of the test specimens. In the DDM process, the copper powder is melted by a plasma jet and accelerated in the direction of the workpiece surface.

These coated samples were then fitted with LEDs and successfully tested for their electrical conductivity and electrical resistance. The adhesive strength of the copper layers produced was also analysed. When comparing the different compounds, the decision was made in favour of PA6 with 30 wt.% glass fibre filler in terms of conductivity and adhesive strength, despite the slightly lower thermal conductivity compared to PBT and PA66.

In order to analyse the three-dimensional properties of this material, an appropriate filament for 3D printing must be produced.

Prüfung der Beschichtung und Optimierung Prozessparameter

For the subsequent use of the lamp bodies in lighting systems, the adhesive strength of the coating must be guaranteed over the product life cycle. Test specimens were subjected to various tests for validation:

- Mechanical testing

- Temperature/humidity storage

- Accelerated ageing due to weathering

- Visual inspection

The results showed that although the appearance of the coating becomes discoloured due to oxidation, there is no deterioration in electrical conductivity or increased resistance. In addition to the tests, the coating was optimised to such an extent that an almost identical layer thickness of the copper conductor track was achieved on the base body. This forms the basis for a consistent current-carrying capacity for the LEDs still to be fitted.

Filament production and prototyping using additive manufacturing

A filament was produced from the in-house compounded material for prototype construction. The experience and support of Pappenheimer Kunststoffmaschinenvertrieb (PKV) was used to realise the required constant filament diameter of 1.75 mm for the fused filament fabrication (FFF) process. When manufacturing the prototypes, the challenge lay in the surface roughness of the manufactured components so that optimum adhesion of the 3D coating could subsequently be achieved.

Masking and coating of the 3D base body

In order to apply the desired circuit layout to the 3D bodies using plasma coating, a corresponding steel mask was produced using additive manufacturing at the DIT Technology Campus in Cham. After programming the integrated KUKA robot for the three-dimensional coating, the conductor track design developed by the partner Dotlux could be applied to the base body. Several lamp body shapes were realised for different areas of application, each with an adapted conductor track layout. By systematically varying the process parameters of current supply, gas flow, feed rate or distance between the nozzle and substrate, a low-resistance and electrically conductive coating was achieved.

Fitting and photometric inspection

The assembly of the 3D bodies presented a number of challenges. These included attaching the LEDs to the exact contact positions and finding the right soldering temperature without damaging the base body too much. Once the LEDs had been successfully attached and contacted, the lighting inspection by the TÜV was successfully completed.

Please contact us for further information!!!

M.Sc. Dominik Weiß

Prof. Dr. Dmitry Rychkov

Partner

The Technology Campus (TC) Hutthurm of the Deggendorf Institute of Technology is a key element of the Kunstoff Campus alongside the Technology Centre (TZ) Weissenburg. The TC Hutthurm cooperates on research and development topics relating to resource efficiency through process development, lightweight construction and materials research.

At kunststoffcampus bayern, the founding partners, Deggendorf Institute of Technology, Ansbach University of Applied Sciences, the district of Weißenburg-Gunzenhausen and the town of Weißenburg work closely together with the cooperation partners IHK-Akademie Mittelfranken and bfz Westmittelfranken gGmbH.

The Ansbach University of Applied Sciences operates the Study Centre (SZ) Weissenburg. Together with educational institutions such as the IHK-Mittelfranken and the Fachschule für Kunststofftechnik und Faserverbundtechnologie, Ansbach University of Applied Sciences offers a wide range of training and further education courses in the region. Examples include the part-time Bachelor's degree programmes in Applied Plastics Technology and Strategic Management at Ansbach University of Applied Sciences. Prof Dr Stefan Slama is currently the scientific director and Prof Dr Thomas Müller-Lenhardt is the deputy scientific director of the SZ.

- The part-time degree programme "Applied Plastics Technology" is a broad-based and practice-oriented degree programme that prepares students for a wide range of jobs in the plastics industry - both as a manager and as a technical expert. Engineering and business fundamentals are supplemented with modules for personal development and profile modules that include specialised knowledge from the plastics sector. Degree: Bachelor of Engineering (B.Eng.)

- The "Strategic Management" course deals with the holistic optimisation of internal and cross-company processes on the basis of the EFQM (European Foundation for Quality Management) model for business excellence. The programme teaches very practice-oriented process and methodological knowledge with business management content for sustainable corporate management at the highest level. Degree: Bachelor of Arts (B.A.)

The IHK Academy offers the right training programme for every stage of life: Master craftsman training (e.g. industrial foreman), business administration, training of trainers and seminars (e.g. modern employee management) are available at various locations in Middle Franconia. At the kunststoffcampus bayern, the IHK Academy sees an opportunity to bring together and network experts from practice, universities and research. For example, master craftsmen can take part in research projects and get in touch with the study programme in advance. The IHK Academy also wants to promote cooperation with the partners of the kunststoffcampus bayern in order to create joint event and learning formats.

- The "Certified Industrial Foreman Plastics/Rubber (IHK)" practical study programme gives you the opportunity to qualify for a management position in a company in the plastics and rubber industry. If you have completed a recognised apprenticeship in the plastics industry, you will gain a sound, broad-based knowledge base. You will be able to perform technical, organisational and management tasks in companies of different sizes and in different areas and fields of activity within a company. You will be able to adapt to changes in methods and systems in production, to new structures of work organisation and to new methods of organisational development, personnel management and development and to help shape technical and organisational change in the company. Qualification: Certified industrial foreman in plastics/rubber (IHK)

- Further training to become a technical business administrator is aimed equally at those interested in commercial and technical professions with relevant professional experience and a personal aptitude for the other area. Qualification: Technical Business Administrator (IHK)

The bfz Fachschule für Kunststofftechnik und Faserverbundtechnologie (Technical College for Plastics Engineering and Fibre Composite Technology) offers skilled workers in the plastics sector the opportunity to take advantage of the varied course content of the part-time advanced training to become a technician specialising in plastics technology and fibre composite technology under the umbrella of the kunststoffcampus bayern. The training programme starts every two years in September, lasts four years and enables entry into middle management.

NEWS

In Hutthurm entsteht ein neuer Technologiecampus

In Hutthurm entsteht ein neuer Technologiecampus

Die Technische Hochschule Deggendorf (THD) wird ihre bisherigen Forschungs- und Entwicklungsaktivitäten im Bereich der „Polymeren Werkstoffe und deren Anwendung“ ausweiten. Als Außenstelle des in Weißenburg-Gunzenhausen bereits bestehenden Technologiezentrums wird im Markt Hutthurm ein weiterer Technologiecampus (TC) für Kunststofftechnologie eingerichtet. Der Startschuss fällt voraussichtlich im Frühjahr 2019.

„20 Technologiecampus gibt es insgesamt in Bayern, die Hälfte davon betreibt alleine die THD“, berichtete THD-Präsident Sperber im Rahmen eines gemeinsamen Pressegesprächs am „kunststoffcampus“ in Weißenburg nicht ohne Stolz. Der zehnte und jüngste Standort wird im kommenden Jahr im Markt Hutthurm an den Start gehen und gemeinsam mit dem Technologiecampus in Weißenburg-Gunzenhausen unter der Marke „kunststoffcampus bayern“ agieren.

Die bisherigen technologischen Schwerpunkte am TC in Weißenburg liegen unter anderem in der Entwicklung und Herstellung neuer Kunststoffcompounds, der Direktmetallisierung, dem Bewitterungs- und Alterungsverhalten von Kunststoffen, der Oberflächenmodifizierung sowie bei temperaturüberlagerten Bewegungsstudien von Kunststoffmodulen. Dem gegenüber soll sich das neue Technologiezentrum in Hutthurm zunächst auf die Simulation von komplexen Fließprozessen in der Kunststofffertigung, die Herstellung von Leichtbaustrukturen und auf die Digitalisierung von Fertigungsprozessen und Materialströmen konzentrieren. Als Querschnittsthema für beide Einrichtungen gilt die Entwicklung von nachhaltigen und ressourcenschonenden Produktionsprozessen im Bereich der Kunststofftechnik.

Ziel der THD ist es, kunststoffverarbeitenden Unternehmen ein möglichst breites Kompetenzprofil für die Durchführung von Forschungs- und Entwicklungsvorhaben zu bieten. Gleichzeitig soll ein Höchstmaß an Synergien zwischen den beiden Technologieeinrichtungen erzeugt werden. Deshalb werden unter der Verantwortung des bisherigen Fachlichen Gesamtleiters des „kunststoffcampus bayern“ im Technologiezentrum in Weißenburg, Prof. Dr. Christian Wilisch, zentrale Verwaltungsstrukturen zur Steuerung der beiden Einrichtungen aufgebaut. Zur Erleichterung der Gesamtkoordination werden außerdem beide Technologiezentren unter eine eigene wissenschaftliche Leitung gestellt. Beim Technologiezentrum in Weißenburg hat diese Aufgabe Prof. Dr. Sigrid Schwub übernommen, die Ende des vergangenen Jahres von der TH Deggendorf zur Professorin für das Lehrgebiet Werkstoffwissenschaften berufen wurde. Die wissenschaftliche Leitung für das neue Technologiezentrum in Hutthurm soll im Laufe des Jahres gesucht und berufen werden.

Prof. Sperber, Landrat Franz Meyer (Landkreis Passau), Landrat Gerhard Wägemann (Landkreis Weißenburg-Gunzenhausen), Oberbürgermeister Jürgen Schröppel (Weißenburg) und der Erste Bürgermeister des Marktes Hutthurm, Hermann Baumann, zeigten sich zuversichtlich, dass die neue Außenstelle des „kunststoffcampus bayern“ in Niederbayern ein wichtiger Technologiepartner für die dortige heimische Industrie werden wird. Aber selbstverständlich werden die Synergieeffekte die anwendungsorientierte Forschung an beiden Standorten stärken und somit auch die weitere Einwerbung von Fördermitteln aussichtsreicher machen.

Neben der Berufung eines wissenschaftlichen Leiters für den Standort Hutthurm sind die Herrichtung des bereits bestehenden Industriegebäudes im Gewerbegebiet des Marktes Hutthurm sowie weiterführende Diskussionen mit regionalen und überregionalen Industriepartnern zur fachlichen Ausrichtung die vordringlichsten Aufgaben, die in den nächsten Monaten für das „kunststoffcampus bayern“ anstehen.

Der Freistaat Bayern unterstützt den Aufbau des neuen Technologiezentrums in Hutthurm mit einer staatlichen Anschubfinanzierung. Der Landkreis Passau erklärte sich im Zuge des Projektförderantrages dazu bereit, gemeinsam mit dem Markt Hutthurm den kommunalen Part der Anschubfinanzierung zu übernehmen. Bei einer Laufzeit von fünf Jahren wird dabei mit Kosten von bis zu 300.000 Euro gerechnet.

04. April 2018 | THD-Pressestelle (JK)

Startschuss für das mit 1,75 Mio. Euro geförderte Projekt „Nachhaltige Wertschöpfungskette“ am kunststoffcampus in Weißenburg

Am 21.02.2017 findet ab 13:00 Uhr die Auftaktveranstaltung des Projekts 'Nachhaltige Wertschöpfungskette' am kunststoffcampus in Weißenburg statt. Das Projekt wird mit 1,75 Mio Euro europäischer Fördermittel bezuschusst.

Interessierten Unternehmen werden die Kooperationsmöglichkeiten sowie die bisherige maschinelle Ausstattung des Kunststoffcampus vorgestellt. Im Rahmen mehrerer Innovationsworkshops werden zudem für die Unternehmen relevante, konkrete Ansatzpunkte erarbeitet. Eine Teilnahme ist nur nach vorheriger Anmeldung möglich.

20. Februar 2017 | THD-Pressestelle (CM)

Im kunststoffcampus bayern in Weißenburg fand nunmehr eine Sitzung des Forums Wissenschaft der Europäischen Metropolregion Nürnberg statt. In seiner Doppelrolle als Gastgeber sowie als Politischer Sprecher des Forums Wissenschaft freute sich Landrat Gerhard Wägemann, neben dem Fachlichen Sprecher Prof. Dr. Godehard Ruppert (Präsident der Universität Bamberg) und dem Forum-Geschäftsführer Horst Müller (Wirtschaftsreferent der Stadt Fürth) eine Reihe von Vertreterinnen und Vertretern der Hochschulen und wissenschaftlichen Einrichtungen der Metropolregion im kunstoffcampus in Weißenburg begrüßen zu können.

Im Rahmen seiner Begrüßung der Forumsteilnehmer erläuterte Landrat Wägemann kurz die Entstehungsgeschichte des kunststoffcampus bayern als regionales Leuchtturmprojekt und wies auf die Bedeutung dieser Einrichtung zur Fachkräftesicherung sowie für den Technologietransfer in der regionalen Kunststoffbranche hin. Im Vorfeld der Sitzung hatten die Mitglieder des Forums die Gelegenheit, das Leistungsspektrum des kunststoffcampus mit seinem Technologie- und Studienzentrum im Rahmen einer Führung mit dem Fachlichen Gesamtleiter, Prof. Dr. Christian Wilisch, näher kennenzulernen.

In den Sitzungen des Forums wird neben einigen Leuchtturmprojekten intensiv diskutiert, wie die Wissenslandschaft der Europäischen Metropolregion Nürnberg mit ihren 37 Hochschuleinrichtungen in der öffentlichen Wahrnehmung noch besser vermittelt werden kann. Die Bandbreite reicht dabei von Institutionen wie der Universität Erlangen-Nürnberg über Forschungs- und Bildungseinrichtungen bis hin zu kleinen Studien- und Forschungseinrichtungen, wie z.B. den kunststoffcampus bayern in Weißenburg. Da die Wissenschaft in der Metropolregion sehr breit gestreut ist, geht es darum, die verschiedenen Interessenslagen und Kompetenzen der Einrichtungen herauszuarbeiten und miteinander zu vernetzen. Weiterer zentraler Schwerpunkt der Forumsarbeit liegt darin, das technologische Entwicklungsleitbild auf dem Gebiet der Metropolregion fortzuschreiben und zu begleiten. Einmal im Jahr veranstaltet das Forum Wissenschaft den Wissenschaftstag der Europäischen Metropolregion Nürnberg, der durch die Hochschulstandorte der Metropolregion zieht und Entscheidern aus Politik, Wirtschaft, Forschung und Bildung dabei als Plattform zum Netzwerken und Ideenaustausch dient. In der Forumssitzung im kunststoffcampus bayern erfolgte u.a. ein Rückblick auf den Wissenschaftstag 2016 an der Universität Bayreuth sowie ein Ausblick auf die laufenden Vorbereitungen des anstehenden Wissenschaftstages, der am 28.07.2017 an der Universität Bamberg stattfinden wird.

Über die Metropolregion Nürnberg

Die Metropolregion Nürnberg, das sind 23 Landkreise und 11 kreisfreie Städte – vom thüringischen Landkreis Sonneberg im Norden bis zum Landkreis Weißenburg-Gunzenhausen im Süden, vom Landkreis Kitzingen im Westen bis zum Landkreis Tirschenreuth im Osten. 3,5 Millionen Einwohner erwirtschaften ein Bruttoinlandsprodukt von 118 Milliarden Euro jährlich –die Metropolregion Nürnberg liegt damit 20 Prozent über der Wirtschaftskraft von Ungarn. Eine große Stärke der Metropolregion Nürnberg ist ihre polyzentrale Struktur: Rund um die dicht besiedelte Städteachse Nürnberg-Fürth-Erlangen-Schwabach spannt sich ein enges Netz weiterer Zentren und starker Landkreise. Die Region bietet deshalb alle Möglichkeiten einer Metropole – jedoch ohne die negativen Effekte einer Megacity. Bezahlbarer Wohnraum, funktionierende Verkehrsinfrastruktur und eine niedrige Kriminalitätsrate machen die Metropolregion Nürnberg für Fachkräfte und deren Familien äußerst attraktiv.

Bildunterschrift:

Der Fachliche Gesamtleiter des kunststoffcampus bayern, Prof. Dr. Christian Wilisch, stellte den Mitgliedern des Forums Wissenschaft im Rahmen einer Führung durch das Technologie- und Studienzentrum das gegenwärtige Leistungsspektrum des kunststoffcampus vor.

26. Januar 2017 | Pressemitteilung Lra. Weißenburg-Gunzenhausen

Spatenstich für den "Kunststoffcampus Bayern" in Weißenburg.

Von einem Meilenstein war am Sonntag im Weißenburger Gewerbegebiet West mehrfach die Rede. „Weißenburg wächst jetzt tatsächlich zum Hochschulstandort“, unterstrich Landrat Gerhard Wägemann. Und Oberbürgermeister Jürgen Schröppel sprach angesichts dieser Tatsache von einem „historischen Moment“. Anlass war der Spatenstich für den „Kunststoffcampus Bayern“.

Die Kombination eines Technologietransfer- und eines Studienzentrums ist bayernweit bisher einmalig. Dass das Projekt deutliche Strahlkraft über die Region hinaus hat, zeigte auch die Tatsache, dass der Bayerische Rundfunk den Spatenstich vermeldete.

Zu dem Ereignis waren Vertreter der beiden beteiligten Hochschulen, der Wirtschaft, des bayerischen Wirtschaftsministeriums, der Planungsbüros und des Generalunternehmers, Mitarbeiter des Landratsamts und der Stadtverwaltung, Aufsichtsräte sowie Nachbarn eingeladen.

Der Ausbau des „Kunststoffcampus Bayern“ zu einem „international anerkannten Bildungs-, Forschungs- und Entwicklungszentrum, die Vernetzung mit der Industrie, die Erarbeitung und Durchführung von maßgeschneiderten Lehrangeboten und die Durchführung von Forschungs- und Entwicklungsaufträgen aus der Industrie stehen im Vordergrund des Kooperationsvorhabens der Technischen Hochschule Deggendorf und der Hochschule für angewandte Wissenschaften Ansbach“, skizziert eine Pressemitteilung das Vorhaben.

Die Freude und die Erleichterung über den Baubeginn war am Sonntag allen Verantwortlichen anzumerken, denn den bisherigen Weg des Projektes prägten einige Stolpersteine. „Wir mussten so manches Auf und Ab erleben bis wir zu diesem Spatenstich kamen“, schilderte Landrat Wägemann, der auch Aufsichtsratsvorsitzender der TSZ Weißenburg GmbH ist. Und OB Schröppel bekundete mit den Worten „das Projekt ist meiner Haarfarbe nicht zuträglich“, dass ihm der Kunststoffcampus Bayern manch graues Haar wachsen ließ und ihm

Als das Vorhaben im November 2011 vorgestellt wurde, sah alles schon festgezurrt aus. Der damalige Finanzminister Georg Fahrenschon hatte die Finanzierung zugesichert. Doch Anfang 2012 hatte im Münchner Wissenschaftsministerium niemand mehr die vereinbarte Summe im Gedächtnis.

Wägemann kämpfte unnachgiebig und nach zähem Ringen standen wieder die ursprünglich zugesicherten 7,5 Millionen Euro zur Verfügung (5,5 Millionen Euro Anschubfinanzierung und zwei Millionen für die Personalkosten in den ersten fünf Jahren). Der Freistaat zahlt sogar das Personal in den Folgejahren.

"Da war das Tal der Tränen erstmal erreicht"

Doch es sollte weiteres Ungemach folgen. Als die ersten Kostenschätzungen um den Jahreswechsel 2012/ 2013 eingingen, war man „weit von dem entfernt, was budgetiert war“, schilderte Markus Hertlein von der Firma HSP Projektmanagement und Beratung, die das Vorhaben steuert. „Da war das Tal der Tränen erstmal erreicht.“ Man habe gemeinsam alles nochmals überprüft, nach weiteren Synergieeffekten gesucht und schließlich „eine deutliche Reduktion der Fläche“ erreicht. An der Qualität wurden aber keine Abstriche gemacht, versicherte Hertlein. „Wir bekommen ein sehr effizientes Gebäude.“

Als erfreulich werten alle Beteiligten, dass bei der Vergabe trotz der sehr guten Baukonjunktur und den damit verbundenen hohen Preisen der vor- gegebene Kostenrahmen eingehalten wurde. Der TSZ-Aufsichtsrat hatte sich einstimmig für die Vergabe der europaweit ausgeschriebenen Generalunternehmerleistungen an das Hoch- und Tiefbauunternehmen Bachl im niederbayerischen Röhrnbach ausgesprochen.

Gerhard Feld, Geschäftsführer der TSZ Weißenburg GmbH, nannte Bruttokosten von 15 Millionen für das „Leuchtturmprojekt“. Stadt und Landkreis müssen davon 8,5 Millionen Euro gemeinsam schultern. Für den ehemaligen Kreiskämmerer war es „ein politisches Meisterstück, das Wissenschaftsministerium für dieses Projekt zu gewinnen“. Er dankte ausdrücklich OB Schröppel und Landrat Wägemann, der Stadt- und der Kreisverwaltung sowie den Hochschulen Deggendorf und Ansbach für die konstruktive Zusammenarbeit.

Viel Lob für Gerhard Feld

Im Gegenzug gab es sowohl von den Hochschulen, als auch von Schröppel und Wägemann viel Lob für Feld: Er habe in der ihm eigenen Art das Vorhaben vorangetrieben, sagte der Landrat. Wägemann dankte aber auch dem Wirtschaftsministerium für die Standortentscheidung, die Anschubfinanzierung und die Dauerfinanzierung des Personals, den Mitarbeitern im Landratsamt und der Stadtverwaltung sowie dem OB „für die unkomplizierte Zusammenarbeit“. Schröppel ist ebenfalls von der Kooperation über Partei- und kommunale Grenzen angetan.

Die Hochschulvertreter bescheinigten den Verantwortlichen vor Ort großen Kooperationswillen und Zielstrebigkeit. Professor Dr. Peter Sperber, Präsident der Technischen Hochschule Deggendorf, hat die Zusammenarbeit mit Wägemann „immer Spaß gemacht“. An den Landrat gerichtet sagte er: „Ohne ihre Durchsetzungskraft hätten wir es nicht geschafft. Glücklicherweise wussten wir beide immer, was wir wollen.“

Sperber ist überzeugt, dass mit dem Kunststoffcampus „wirklich etwas Besonderes für Bayern“ entsteht. Er ist zuversichtlich, dass das Konzept aufgeht. Bereits bestehende Campi würden sehr gut angenommen und erhielten viele Aufträge aus der Industrie.

Mit der gelte es nun Kontakte zu knüpfen. Erste Unternehmen seien schon auf ihn zugekommen, schilderte Professor Dr. Christian Wilisch, fachlicher Gesamtleiter des „Kunststoffcampus Bayern“. Er sprach dem Landkreis und der Stadt seine Anerkennung für die große Investition aus: „Es gehört Mut dazu, so viel Geld in die Hände zu nehmen.“

Er und alle anderen Redner hoffen auf einen unfallfreien Bau des Campusgebäudes mit einer Geschossfläche von rund 3400 Quadratmetern, das in einer „sehr ambitionierten Bauzeit von gut 14 Monaten“ (Gerhard Feld) entstehen soll.

Quelle: nordbayern.de

Foto: Foto: Renner

Directions

Deggendorf Institute of Technology

kunststoffcampus bayern

Weißenburg Centre of Technology

Richard-Stücklen-Straße 3

91781 Weißenburg

Tel.: 09141 -874669 -0

Fax: 09141 -874669 -169

info@kunststoffcampus-bayern.de

https://www.kunststoffcampus-bayern.de/

Flyer - range of services kunststoffcampus bayern (in German)