DIT Research

Pioneering & Vibrant

The Fraunhofer Application Center CT in Metrology (CTMT) at the Deggendorf Institute of Technology (DIT) in Lower Bavaria is a branch directly affiliated with the Fraunhofer Development Center X-ray Technology (EZRT) and is this part of one of the largest research facilities for X-ray technology worldwide.

Especially in the areas of application and further development of industrial X-ray computed tomography (CT), Deggendorf can now draw on a wealth of experience of almost 10 years. This includes innovative industrial services (CT measurement technology, non-destructive material testing, defect and damage analyses) as well as application-oriented collaborative and contract research.

The connection to the Fraunhofer EZRT also offers access to further high-performance CT systems and resources.

The main tasks of the scientists at the application centre include research work in the field of CT metrology, the implementation of industrial projects and the practical training of future engineers at DIT in the context of lectures, internships and theses or employments as student assistants.

Key Competences

The key competences of the Fraunhofer Application Center CT in Metrology (CTMT) lie not only in special machine construction and system and plant control, but also in metrology, robotics, image processing and AI as well as in the implementation of innovative measurement services.

System and Plant Control

Innovative Measurement Service

Special Machine Construction

Metrology, Robotics, Image Processing and AI

Research Areas

The research interest of the Fraunhofer Application Center CT in Metrology (CTMT) focuses on the following aspects related to CT:

- CT for retail

- Innovative robotic CT for large objects

- CT in metrology and geometry calibration

- Condition detection of batteries and cells using CT analysis

- AI for the automatic evaluation of CT scans

- CT in industry 4.0

- Fast automated CT systems

- CT automation

Research Projects

Our current research projects with their people of contact:

Contact: Martin Leipert

Publications (in German)

Services

You have an idea or a problem, but don't know whether it can be implemented or solved? Our experts accompany you from an initial feasibility study through a development concept to the finished product.

Your contact person for scientific services is Peter Hornberger.

With our services at the Fraunhofer Application Centre CT in Metrology, we make a decisive contribution to increasing the quality and productivity of your products and processes, to minimising risks, to checking compliance and, last but not least, to accelerating the market launch of innovative products.

You too can be one of our customers who benefit from our service portfolio in the field of non-destructive testing at the highest level.

We have a wide range of different X-ray systems at our disposal, with which we master the most diverse inspection tasks. Here, non-destructive testing succeeds from delicate objects to bulky items. Whether it is automobiles, energy production, food, clothing or aerospace: Our scientists offer you the right solutiont, regardless of the application and material.

- Test measurements on random samples

- Test concepts for new components

- Process comparison for the selection of the right inspection technique

- Determining the possibilities and limits of modern X-ray technology for a specific inspection task

- Short response times to customer enquiries and prompt evaluation and preparation of the results - also in the form of customer-specific reports

- Location near you

- Production-related consulting in the field of non-destructive testing

- Flexible range of X-ray systems and testing methods

- Experienced service personnel familiar with industrial production processes

- Application of the innovative and continuously developed technologies of the Fraundorfer Development Centre for X-ray Technology

- Development of innovative solutions for customer-specific problems

Tomoscope HV 500 - Werth | 225 kV Microfocus

- Dimensional metrology (MPEE3: [4.5+L/75] μm) and defect analysis on components with edge

lengths up to 500 mm - With placement robot for fully automated series measurements

Inline-CT – Heitec PTS/Fraunhofer | 450 kV Macrofocus

- Automatable CT system for fast, production-integrated serial measurements

- Also suitable for larger, metallic components and for metrological applications

Tomolibri – Zeiss/Fraunhofer | 300 kV Microfocus – 3K Detector

- With walk-in radiation protection cabin and integrated system for condition monitoring

- High-resolution measurement technology and defect analysis also for larger, metallic components

- Photogrammetry - setup for data fusion of optical images and CT data

Modular sub-micro CT System from Fraunhofer | 150 kV Microfocus

- For measurement of microstructures (resolution up to 0.3 µm/voxel)

ValuCT – VJ Technologies/Fraunhofer | 160 kV Mini focus

- Easy handling with full range of functions

- For teaching and demonstration purposes at the Deggendorf Institute of Technology

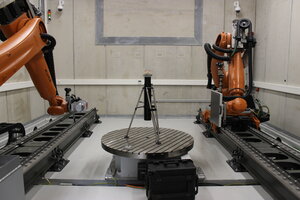

RoboterCT – Streicher/Fraunhofer | 225 kV Variofocus (from Q4/2019)

- Novel, flexible multimodal measuring system for the acquisition of small areas on large test objects up

to the size of a car - Intelligent trajectories to increase image quality

VG Studio MAX

- Visualisation and processing of CT data

- Dimensional metrology, wall thickness analysis, material testing (blowholes), material analysis

Avizo for Material Science

- Complex segmentation of multi-material components

- Fibre analyses

Simpleware

- Intelligent mesh generation for the use of CT data in FE simulations

WinWerth

- Automatable metrological evaluations 2D/3D

Geomagic Studio

- Reverse engineering

- STL data processing

Geomagic Qualify

- Metrological evaluations

ANSYS

- FE simulation environment for system optimisation, virtual testing

ZEISS Reverse Engineering

- Reverse engineering applications

ISG Virtuos

- Development of digital images of real systems for virtual commissioning

Our scientists offer you application- and material-independent solutions for the following industries, among others:

- Plant and apparatus engineering

- EDP and EDP accessories

- Power generation

- Electrical appliances and electrical industry

- Vehicle industry and suppliers

- Building construction and civil engineering

- Cosmetics and hygiene

- Plastics industry and plastic goods

- Food industry

- Aerospace industry

- Mechanical engineering

- Fashion industry and clothing

- Furniture industry

Contact

- Acting director: Dr Steven Oeckl

- Scientific Services: Peter Hornberger

- Further information about the Fraunhofer Application Centre CT in Measurement Technology (CTMT) scan be found at Fraunhofer Development Centre X-Ray Technology (EZRT)